Industrial turbines may not seem like the most exciting topic. But when you start digging around into what these large turbines are actually used for, things get interesting.

Turbines have a long history that has now widened out into a range of uses. Before we get to the what and how of these machines, let’s talk about where they’re used today.

Jet Engines and Rocket Ships

Gas turbines form the basis of the most widely used forms of aircraft propulsion systems. This includes Turbofans, turboprops, turbojets, and afterburning turbojets. While system designs vary, they all use a combustion section, a compressor, a turbine, and an inlet/nozzle.

One kind of gas turbine engine is the Merlin 1. The most recent version of this engine, the Merlin 1D, power up through an open-cycle gas generator turbine. Merlin 1D engines propel both the first and second stage of Elon Musk’s SpaceX missions. This design is very similar to the design used for the Rocketdyne F-1 engines used for the Apollo-era missions.

Submarines-maybe.

International design group BMT has offered up a concept design for a non-nuclear submarine propelled by innovative independent gas turbine-alternators. These semi-submerged gas turbines live in a bulb on top of the submarine’s fin. The turbines burn kerosene and use air brought in through an extendable mast that remains above the waterline.

Power from Water, Wind, Gas, and Steam.

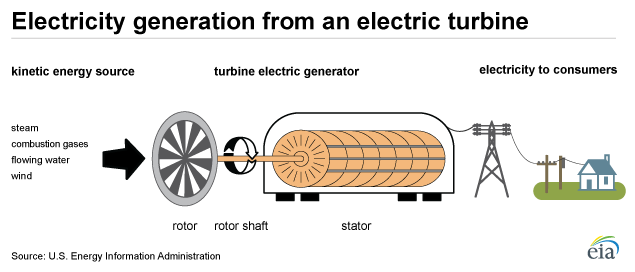

Electricity can begin from many different sources. Regardless of whether it begins with wind, water, or even nuclear power, it probably uses a turbine as part of the system to create electricity from the kinetic movement.

Electricity production occurs in several ways. Wind and hydroelectric plants push the blades directly with a stream of water or air. Nuclear power plants use nuclear fuel to produce steam that then drives the turbine. Combustion turbines or combines cycle turbines use combustion gases from one turbine to create electricity in another.

Backup for Hospitals

It’s frustrating when you’re in the middle of something and your power goes out. But it can be devastating to healthcare providers if a hospital is not equipped with a reliable backup power source.

While most hospitals still rely on some sort of generator backup run on diesel fuel, some have now looked to adding CHP (combined heat and power) systems that can provide onsite generation resources for longer periods. CHP systems use microturbines as the basis of their design. They meet all the hospital’s electrical and thermal needs. In comparison to emergency generators typically sized to offer limited service, CHP systems can keep hospitals running at more efficient levels.

Also, CHP systems are designed to work in conjunction with the power grid on a day-to-day basis. Everyday use leads to more consistent maintenance which, in turn, leads to reliable systems ready for emergencies.

History of Turbines

Steam turbine design goes as far back as the first century AD. But steam engines in practice didn’t come about until the mid-1800s when William Avery modified a patent developed by James Watt fifty years before. With the passing of another fifty years–give or take–Charles Parsons developed his Parsons steam turbine, used for electrical production, naval warfare, and marine transport.

The first industrial gas turbine came online in a municipal power station located in Neuchatel, Switzerland. This was in 1939 when A.B. Brown Boveri installed the simple-cycle turbine. It remained operational until 2002.

There are four basic types of turbines. While each type can then break down into sub-categories, primary typing Each type is based upon its driving force that can be broken down into sub-categories. Additionally, turbines can be categorized by function.

Driving force:

- Steam turbines, used in coal, fuel oil, or nuclear fuel thermal power plants.

- Water turbines, used in hydroelectric plants. Newer water turbines are being used to harness the power of tidal and river flows.

- Francis turbine, developed in 1855. Most common water turbine used today.

- Pelton Wheel, developed in 1880.

- Banki-Michell turbine (cross-flow turbine), developed in 1903.

- Kaplan turbine, developed in 1913.

- Turgo turbine, developed in 1919.

- Wind turbines, which can be designed without a nozzle and guide vanes, or can have a stator and rotor like an Eolienne wind turbine.

- Gas turbines, used in industrial applications and in aerospace. Hot exhaust moves through a nozzle. When used in mechanical applications, a gas turbine’s power is measured in horsepower or HP. When used for power generation, output or power is measured in watts, Kw, or Mw.

- Turbojet

- Turbofan

- Turboprop

- Afterburning Turbojet

- Direct drive

- Mechanical drive

- Aeroderivatives, designed as a smaller, lighter industrial option. These turbines use aerospace technology (higher compression ratios, the capability to frequently start and stop, minimal start-up power requirements) and apply them to industrial applications. As compared to reciprocating engines (aka, piston engines) aeroderivatives offer significantly lower particulate matter and unburnt hydrocarbons, both of which can contribute to greenhouse gas generation.

Industrial Turbines by Function:

- Impulse turbines work according to the idea that acceleration occurs when a force acts upon an object in direct relation (Newton’s 2nd law.) The moving force (most often water) strikes the ends of the rotor hub, changing kinetic energy into mechanical energy. A Pelton turbine is an impulse type turbine.

- Reaction turbines use specially designed rotor blades that generate a force as water, air, or something else flows over them. A Kaplan turbine is a reaction turbine.

- Horizontal-axis wind turbines (HAWT)

- Darrieus vertical-axis wind turbine (Darrieus VAWT)

- Savonius vertical-axis wind turbines (Savonius VAWT)

- Open cycle gas turbines, that allow exhaust gases to vent to the outside.

- Closed cycle gas turbines, that reuse exhaust gases for reheating. These are often used in power plants.

This is simply an introduction to turbines. Turbines are used in so many applications it is impossible to cover them all. And every year brings more technological breakthroughs and new applications to this old technology.

Industries that Use Turbines

Many industries rely on turbine applications. Although we’ve mentioned several in the paragraphs above, here’s a list of some of the most turbine-dependent industries:

- Green energy sector

- Hydroelectric power

- Nuclear power

- Aviation

- Healthcare/hospitals

- Military

- Oil and Gas industries

Need backup industrial turbine parts? We can help with that. Talk to our team today.